Company Profile

NANJING PEGE TECHNO MACHINE CO., LTD is a leading quality and customer-oriented manufacturer and supplier who is specialized in providing rubber and plastic industry machines. Rubber sector machines focus on deburring and cutting include cryogenic de-flashing machine, spin trim de-flashing machine as well as rubber strip or gasket cutting machine. Plastic sector machines focus on material precision feeding include the Gravimetric Loss-in-weight feeders and its affiliated system including uploading and supplementary system.

Cryogenic Deflashing Machine aims at realizing faster quality production cycle with least rejection on those parts including rubber molded, plastic injection molded and die-casting components' flashes removal process.

Meanwhile, NANJING PEGE is among the top cryogenic de-burring machine supplier in the world with more than 10 years of experiences and its machine has been widely accepted by the customers domestically and internationally.

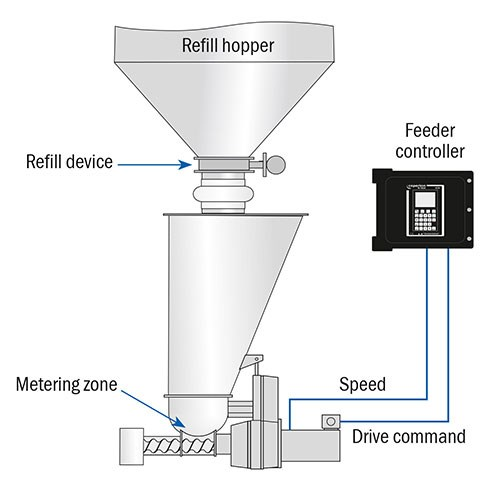

Our plastic machine department also continuously develops and optimizes the Gravimetric loss-in-weight feeding machine to meet the customer demand to improve feeding efficiency and reduce labor work tense as well labor cost.

Gravimetric Feeder is widely applied in the industry of Plastic, Chemistry, Food and Pharm, used for material precision mixing, dosing and feeding application.

By using world well-known brand components and high professional production technology, all the machines produced by NANJING PEGE company are of reliable quality and high stability with the features of Lower energy consumption as well as less maintenance cost. With the efforts from our sales and production team, the "Frozen Shot" brand PG series cryogenic deburring machine, ‘PG’ brand Gravimetric Feeder are sold not only in the domestic China market, but also many other countries like Indonesia, Malaysia, Thailand, Poland, Russia, Croatia, Colombia and more from all over the world.

We keep building highly efficient systems which work to save resources based on intelligent technologies and thus we can contribute to the efficient production and protection of the environment in the customer end.

We believe that high quality and reliable machine from NANJING PEGE will serve all the customers worldwide to help them improve efficiency, precision and lower labor cost.

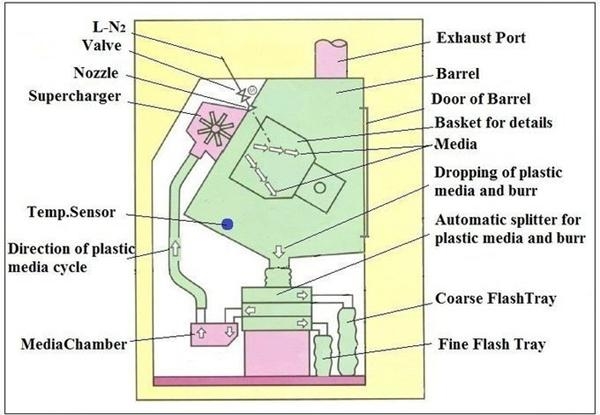

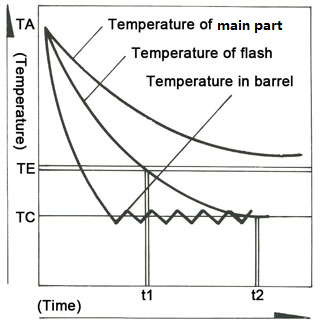

Cryogenic Deflashing Work Principle

With the decrease of the temperature, rubber/plastic parts enters into hardened, brittle, and crystallized process, its flexibility is gradually lost. It is easily broken by external force when it is under brittle temperature. Flash of the molded products is generally much thinner than finished product itself, it become brittle earlier than product in the low temperature. Cryogenic deflashing machine applies this principle, works in the time range when flash is brittle while products still keeps its flexibility, hit the flashes by high speed projected special plastic media, clear out the brittle burr. The flashes can be easily removed and the product not be damage.

The measuring hopper is mounted on a platform scale (frame structure equipped with precision sensors). When the feeder is running, the motor drives the feeding screw or pump to move. At the same time, the material in the measuring hopper flows out. By reducing the weight in the unit time, obtain the actual feeding amount, compare it with the set feeding amount to get the error value, and then adjust the speed of the feeding motor through the PID closed-loop control algorithm to achieve the precise feeding requirements. This process ensures an accurate feeding or dosing during the production process.

Vision:

To become a reputed and dynamic enterprise with an international sight.

Mission:

To lead an automatic, efficient, eco-friendly production technology for worldwide precision products manufacturers.

Our Value

|